- #L298N MOTOR DRIVER BOARD PYTHON HOW TO#

- #L298N MOTOR DRIVER BOARD PYTHON DRIVER#

- #L298N MOTOR DRIVER BOARD PYTHON FULL#

- #L298N MOTOR DRIVER BOARD PYTHON SOFTWARE#

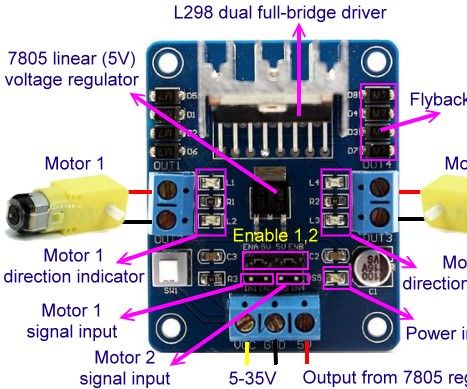

Which connection configuration you choose will depend largely on the number of PWM channels you want to use. The L298N H-Bridge module, like in the image below, has two connection configurations available. So, test the electrical characteristics of any H-Bridge module before connecting to the Raspberry Pi. There are other popular H-Bridge modules about but not all are compatible with the Raspberry Pi. This H-Bridge module is compatible with the Raspberry Pi, however, other L298N configurations might not be as compatible. You can get more information about this module here.

#L298N MOTOR DRIVER BOARD PYTHON DRIVER#

For now, I am just focussing on the H-Bridge control logic.Ī typical H-Bridge module I am using here is an L298N Dual H-Bridge DC motor driver module.

#L298N MOTOR DRIVER BOARD PYTHON FULL#

The full H-Bridge wiring schematic is not included in this case since a full example schematic is shown above.

#L298N MOTOR DRIVER BOARD PYTHON HOW TO#

The Python code examples provided show how to set up PWM for two different H-Bridge configurations.

GPIO PWM Python 3 Code Examples Raspberry Pi and L298N H-Bridge Connection Schematic

I think this is an ideal approach for makers beginning to build their own R/C robot project. Then use GPIO PWM through the GPIO Zero API. In any case, from my own tests, I am confident that I can get some decent DC motor control by attaching an H-Bridge module directly to the Raspberry Pi.

#L298N MOTOR DRIVER BOARD PYTHON SOFTWARE#

But I believe the PWM is software driven using a shared clock source and might involve DMA channels. I admit at this point I do not know how the GPIO PWM is implemented on the Raspberry Pi. GPIO PWM GPIO PWM Output at 1200Hz Frequency

Now, I take a look at how to drive a typical H-Bridge module, connected to a Raspberry, with GPIO PWM. I have already covered R/C controller input using a game controller here. This will help keep the Python code elements of the robot control software modular. Furthermore, it is worth noting to keep hardware driver software code routines separate from robot control logic routines. So, getting a bit of understanding of how the hardware works first will help create the rest of the robot control software. This is especially true where the robot vehicle is a skid steer type. There is a lot that goes on in code between R/C controller input and H-Bridge DC motor driver output. Furthermore, H-Bridge diver code examples with wire connection illustrations are included. Through Python programming, I look at how to interface with a typical H-Bridge DC motor driver. In this article, I look at using the Raspberry Pi GPIO PWM for DC motor control.

0 kommentar(er)

0 kommentar(er)